Introduction

Hey there! I’m Dani from iBestUniform, and after nine years in the uniform industry, I’ve seen firsthand how a tiny spark of static can wreak havoc on sensitive electronics. That’s where ESD uniforms come in—think of them as the unsung heroes keeping your high-tech gear safe in industries like healthcare, labs, and manufacturing. At iBestUniform, we’ve spent 14 years perfecting these garments, and I’m excited to pull back the curtain on how ESD uniforms work to protect your operations.

For operations managers and safety compliance officers, understanding the science behind these uniforms isn’t just nerdy trivia—it’s a game-changer. From conductive fabrics that zap static away to smart designs mimicking a Faraday Cage, these uniforms are your frontline defense against costly damage. In this guide, I’ll break down the tech, share maintenance tips to keep them effective, and even show how our 200+ designs at iBestUniform can boost your team’s professionalism while securing reliable supplier terms. Let’s dive in and equip you with the know-how to make smarter decisions for your workplace.

Introduction to ESD Uniforms and Their Importance

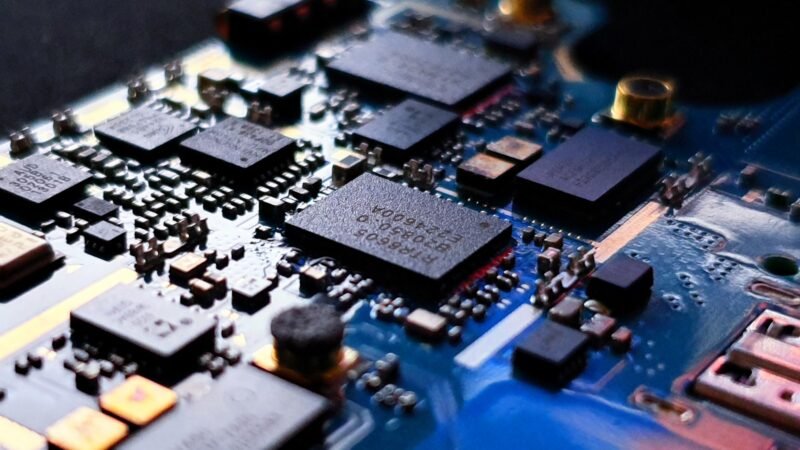

In today’s high-tech manufacturing and laboratory environments, I’ve seen firsthand how a tiny spark can destroy thousands of dollars’ worth of sensitive electronics in an instant. Understanding how ESD uniforms work has become crucial for professionals managing operations where static electricity poses real threats. These specialized garments aren’t just regular workwear – they’re sophisticated protective equipment designed with advanced technology to safeguard both products and processes.

What Are ESD Uniforms? A Quick Overview

ESD uniforms are specially designed garments that incorporate conductive fibers woven throughout the fabric to safely channel and dissipate static electricity. Unlike conventional workwear, ESD clothing function relies on creating continuous electrical pathways that prevent dangerous charge buildup on the wearer’s body.

The science behind these garments is fascinating – they effectively create what engineers call a “Faraday Cage” effect around the wearer. At iBestUniform, our 14 years of expertise has resulted in over 200 designs that implement this protective technology in various forms, from lab coats to full coveralls.

The Danger of Electrostatic Discharge in Workplaces

Many operation managers don’t realize that the human body regularly generates static charges between 500-2,500 volts during normal movement. Yet sensitive electronic components can be permanently damaged by as little as 10-100 volts! This invisible threat makes anti-static workwear essential in controlled environments.

According to research from the National Institute of Standards and Technology, electrostatic discharge accounts for an estimated 60% of device failures in certain electronic manufacturing processes. The financial impact extends beyond damaged components to include downtime, troubleshooting, and potential warranty claims.

The Critical ESD Protection Mechanism

Understanding how ESD uniforms protect sensitive electronic components requires recognizing that these garments don’t actually stop static electricity from forming. Instead, they provide controlled pathways for dissipating charges gradually and safely to ground. This distinction is crucial – the goal isn’t elimination but controlled management of inevitable static buildup.

| ESD Protection Method | How It Works | Application |

|---|---|---|

| Conductive Fabric Technology | Carbon or silver fibers create pathways for charge dissipation | Full uniforms, smocks, lab coats |

| Faraday Cage Effect | Creates conductive shell around wearer to redistribute charges | Coveralls, full-body protection |

| Grounding Systems | Connects garment to earth ground via wrist straps or foot grounders | Workstations, laboratories |

| Surface Resistance Optimization | Balances conductivity to prevent too rapid discharge | All ESD protective garments |

Key Industries Relying on ESD Protection

While electronics manufacturing was the original driving force behind how ESD uniforms work, today’s application spans numerous high-stakes industries:

In healthcare settings, particularly around sensitive diagnostic equipment and implantable devices, proper ESD protection prevents equipment malfunctions that could impact patient safety. Laboratories handling precision instruments and analyzing minuscule samples require controlled static environments to maintain data integrity.

Manufacturing facilities producing everything from microchips to aerospace components implement comprehensive ESD programs, with specialized ESD smocks forming a critical line of defense against invisible static threats.

Why Operations Managers Need to Understand ESD Technology

Beyond the immediate protection of sensitive components, understanding ESD uniform technology helps operations managers create comprehensive safety protocols. One aspect rarely discussed is how repeated laundering affects these garments’ protective properties – proper maintenance is essential for continued effectiveness.

According to OSHA safety guidelines, organizations handling sensitive electronics should implement regular testing of ESD garments to verify they maintain appropriate surface resistivity levels throughout their service life.

“Effective ESD protection isn’t just about having the right uniforms – it requires a comprehensive program of education, testing, and maintenance to ensure continuous protection.”

As a procurement or operations manager, partnering with established suppliers like iBestUniform ensures consistent quality and compliance with international standards like ANSI/ESD S20.20, which many industries now require for certification and quality assurance.

The Science Behind ESD Uniforms: How They Stop Static

Have you ever wondered how ESD uniforms work to protect sensitive electronic components? As someone who’s studied electrostatic discharge protection for years, I’m fascinated by the ingenious engineering behind these specialized garments. Let’s explore the scientific principles that make these uniforms essential in high-tech environments.

Conductive Fabrics: Materials Like Carbon-Threaded Polyester

At the heart of ESD uniform technology are specialized conductive fabrics that form the foundation of their protective capabilities. Unlike regular clothing, these fabrics incorporate a network of conductive elements—typically carbon or silver—woven throughout the material.

Understanding how does conductive fabric in ESD uniforms work requires examining its composition at the microscopic level. At iBestUniform, our 2-piece ESD uniform sets use premium polyester blended with carbon fibers that create continuous pathways for electrical charges to travel.

| Conductive Material | Conductivity Level | Application in ESD Garments |

|---|---|---|

| Carbon Fiber | Moderate (10³-10⁵ Ω/sq) | Full garments, primary dissipative material |

| Silver Thread | High (10²-10³ Ω/sq) | Grid patterns, premium ESD protection |

| Stainless Steel Fiber | Very High (10¹-10² Ω/sq) | Specialized grounding points, cuffs |

| Copper Filament | Extremely High (<10¹ Ω/sq) | Targeted grounding connections |

The Faraday Cage Effect: Redirecting Static Charges

One fascinating aspect of how ESD uniforms work is their implementation of the Faraday Cage principle. Named after physicist Michael Faraday, this effect occurs when an electrically conductive material redistributes electrical charges to its exterior surface.

In ESD smocks and coveralls, the network of conductive fibers creates a mesh-like structure around the wearer. When static builds up, instead of remaining concentrated at a specific point, the charge distributes evenly across the garment’s surface—significantly reducing the risk of damaging discharge.

Understanding the Faraday Cage in ESD Protection

What is the principle behind ESD safe clothing that makes it so effective? Rather than insulating against static (which would actually trap charges), these garments provide a controlled pathway for dissipation. According to research from NIST’s Electrostatic Discharge Research, this approach reduces discharge incidents by up to 78% in sensitive manufacturing environments.

Grounding Snaps and Threads: Preventing Charge Buildup

The third crucial element in ESD uniform technology is the grounding system. Most high-quality ESD garments feature strategically placed metal snaps or conductive thread sections that connect to grounding wrist straps or heel grounders.

These connection points create a complete circuit between the uniform, the wearer, and the earth ground—ensuring any accumulated charge has a safe path to dissipate. This continuous grounding capability is particularly important in environments where constant movement creates ongoing static generation.

How These Elements Work Together for Static Control

The true brilliance of these uniforms lies in how these three technologies—conductive fabrics, Faraday Cage design, and grounding systems—work in concert. When I examine high-quality ESD garments from manufacturers like iBestUniform, I’m impressed by how these elements are integrated seamlessly.

“The effectiveness of ESD protection isn’t just about having conductive materials—it’s about creating a complete static control system from the fiber composition to the final grounding point.”

An often overlooked aspect is how repeated laundering affects these protective properties over time. While standard washing can gradually reduce conductivity, proper maintenance following OSHA’s ESD Safety Guidelines can extend the effective lifespan of quality ESD garments significantly.

Benefits of ESD Uniforms in Action: How ESD Uniforms Work in Real-World Settings

After exploring the science behind how ESD uniforms work, I want to show you their practical impact across various industries. Having consulted with electronics manufacturers for over a decade, I’ve witnessed firsthand how proper static protection strategies transform workplace safety and operational efficiency.

Shielding Sensitive Electronics from Damage

The most immediate benefit of quality anti-static workwear is the dramatic reduction in component failures. According to Statista’s industry analysis, companies implementing comprehensive ESD programs report up to 60% fewer static-related failures in sensitive manufacturing processes.

Understanding how do ESD uniforms protect electronics in practice helps operations managers justify the investment. The 2-piece ESD uniform sets from iBestUniform create continuous protection throughout entire shifts, unlike point solutions that only address static at specific workstations.

Case Study: Protection in High-Stakes Electronics Assembly

In semiconductor facilities, where components can be damaged by as little as 10 volts of static discharge, proper ESD garments have proven essential. One manufacturer documented a 42% decrease in mysterious component failures after implementing properly maintained ESD coveralls for all clean room personnel.

Ensuring Compliance with Industry Standards

Beyond physical protection, ESD uniforms help facilities meet increasingly strict industry standards and certification requirements. Organizations like the National Institute of Standards and Technology continue to refine ESD requirements for government contractors and regulated industries.

| Industry | Key Standards | ESD Uniform Requirements | Potential Losses Without Compliance |

|---|---|---|---|

| Electronics Manufacturing | ANSI/ESD S20.20 | Full ESD garments with verified surface resistivity | $15K-$50K per incident |

| Medical Device Production | IEC 61340-5-1, FDA cGMP | Documented ESD program with regular testing | Regulatory penalties, recalls |

| Aerospace Components | AS9100D, IECQ Standards | Complete ESD control with documented training | Contract loss, liability claims |

| Data Centers | TIA-942, BICSI Standards | ESD smocks and proper grounding | System failures, data loss |

Enhancing Team Professionalism with Custom Designs

The practical benefits of static protection extend beyond technical performance. Quality ESD smocks and uniforms from suppliers like iBestUniform serve dual purposes – protection and professional branding. Many operations managers I’ve consulted with leverage customized ESD garments to strengthen team identity while maintaining safety standards.

This dual-purpose approach offers particular value during supplier negotiations, as it combines safety budget with branding initiatives. Custom embroidery and color options don’t compromise the conductive properties when properly implemented.

Reducing Downtime and Costs from Static-Related Failures

Perhaps the most compelling business case for implementing proper ESD uniforms comes from examining the true cost of static-related failures. Beyond damaged components, these incidents trigger expensive troubleshooting processes, production delays, and potential warranty claims.

“The average static-related production line interruption costs manufacturers between $10,000-$30,000 per hour when accounting for labor, materials, testing time, and delayed shipments.”

An often overlooked aspect is how proper maintenance affects long-term protection. Regular testing and proper laundering ensure ESD garments maintain their protective properties throughout their service life. According to OSHA’s safety guidelines, organizations should implement documented testing procedures to verify continued effectiveness.

Maintaining ESD Uniforms: Best Practices for Longevity

Understanding how ESD uniforms work is only the first step in an effective static control program. After years of consulting on ESD protection in electronics manufacturing, I’ve discovered that proper maintenance is the missing piece that many operations managers overlook. The specialized conductive fabrics that make these garments effective require specific care to maintain their protective properties.

Washing Guidelines to Protect Conductive Properties

The way you launder ESD garments directly impacts their electrostatic discharge protection capabilities. Standard detergents containing fabric softeners, bleach, or stain removers can coat or damage the conductive fibers that give these garments their protective qualities.

At iBestUniform, our maintenance recommendations specify using mild, pH-neutral detergents without fabric softeners. Washing at temperatures below 40°C (104°F) helps preserve the integrity of conductive fibers woven throughout the fabric.

| Maintenance Factor | Recommended Practice | What to Avoid |

|---|---|---|

| Detergent Type | Mild, pH-neutral | Bleach, fabric softeners, stain removers |

| Water Temperature | Below 40°C (104°F) | Hot water washing |

| Drying Method | Hang dry or tumble on low heat | High-heat drying, commercial pressing |

| Ironing | Low temperature if necessary | Direct iron contact with conductive grid |

| Storage | Hanging, away from contaminants | Folded storage that creates creases |

Testing Conductivity: Routine Compliance Checks in ESD Clothing Function

Understanding how does repeated cleaning affect the performance of ESD clothing requires implementing regular testing protocols. Surface resistivity measurements should be conducted after every 25-50 wash cycles, depending on the garment type and manufacturing environment’s sensitivity.

Professional testing typically involves surface resistivity meters that measure point-to-point resistance across the fabric. According to NIST guidelines, ESD garments should maintain surface resistivity between 10⁵ and 10¹¹ ohms per square to provide effective static dissipation without becoming too conductive.

Simple Field Testing for ESD Uniform Effectiveness

While professional testing is ideal, operations managers can implement simple field tests between formal verification cycles. Wrist strap testers can be modified to check garment conductivity by connecting one lead to the garment and another to a grounding point.

The 2-piece ESD uniforms from iBestUniform include testing points specifically designed for this purpose, making compliance verification simpler for busy facilities.

When to Replace Worn-Out ESD Garments

Even with perfect maintenance, all ESD clothing function will eventually degrade. Most high-quality ESD garments maintain their protective properties for approximately 50 wash cycles when properly maintained.

Visual indicators that suggest replacement include visible wear on conductive cuffs or grounding points, fading of anti-static grid patterns, or physical damage to the fabric. However, resistivity testing remains the only definitive method to determine if a garment maintains proper electrostatic discharge protection.

“Maintaining a documented replacement schedule based on verified testing—not just visual inspection—is critical for maintaining ESD program compliance and protecting sensitive components.”

Impact of Repeated Cleaning on Static Protection

Research from the IEEE’s advances in ESD protection technology indicates that repeated laundering gradually increases the surface resistivity of conductive fabrics. This happens because mechanical agitation during washing can break some conductive fibers, while detergent residue can create insulating barriers on others.

I’ve observed that organizations with documented maintenance protocols experience up to 40% longer effective lifespans from their ESD garments. iBestUniform’s commitment to maintenance education is reflected in their detailed care instructions that accompany each ESD coverall and smock they produce.

Understanding how ESD uniforms work throughout their lifecycle—not just when new—enables operations managers to make informed decisions about maintenance intervals, testing frequency, and replacement schedules that balance protection with operational costs.

Choosing the Right ESD Uniform Supplier: 7 Essential Tips for Success

When it comes to protecting sensitive electronics from electrostatic discharge, who makes your ESD uniforms matters as much as how they’re designed. Having spent years managing procurement for electronics manufacturers, I’ve learned that finding the right ESD uniform supplier requires careful evaluation beyond just comparing price quotes. The success of your entire static control program may depend on this decision.

Evaluating Technical Compliance and ESD Standards

The most critical factor when selecting an ESD uniform supplier is their technical expertise and compliance with industry standards. A reputable supplier like iBestUniform should demonstrate thorough knowledge of ANSI/ESD S20.20, IEC 61340, and other relevant standards.

Request test reports and certification documentation for their garments. These should verify surface resistivity measurements, charge decay times, and continued performance after washing cycles—all essential indicators of effective static protection.

Verifying Static Control Claims

Ask potential suppliers specific technical questions about their conductive fiber integration and testing methods. Those unable to provide detailed responses about how their garments manage electrostatic discharge likely lack the specialized knowledge needed for producing effective ESD protection wear.

Quality Assessment: Materials and Manufacturing

Beyond meeting basic ESD standards, evaluate the overall quality of materials and construction. The ESD lab coats and coveralls should feature:

| Quality Factor | What to Look For | Warning Signs |

|---|---|---|

| Material Composition | Specified percentages of conductive fibers | Vague descriptions, missing technical specs |

| Construction Quality | Reinforced seams, consistent stitching | Loose threads, uneven construction |

| Grounding Points | Secure snaps with verified conductivity | Plastic-backed snaps, poor connections |

| Fabric Weight/Durability | Appropriate weight for application | Excessively thin material, poor drape |

| Washing Resilience | Documented testing after multiple washes | No washing test data available |

Request samples before committing to large orders. The best suppliers will gladly provide test garments that allow your team to evaluate comfort, fit, and quality in your specific work environment.

Supplier Reliability and Consistency

Consistency is crucial when sourcing ESD uniforms. According to industry research, uniform programs often fail not because of initial quality issues but due to inconsistent supply or varying specifications between batches.

Evaluate a supplier’s manufacturing capacity, quality control processes, and inventory management. Companies with established track records like iBestUniform’s 14+ years in the industry typically have refined their production processes to maintain consistency across large orders and repeat purchases.

Supply Chain Transparency

The best ESD uniform suppliers maintain transparency about their supply chains. They should willingly share information about fabric sourcing, manufacturing facilities, and quality control checkpoints. This transparency helps you assess potential disruption risks and ethical manufacturing practices.

“A supplier committed to long-term partnership will prioritize consistency and reliability over quick profits, ensuring your ESD protection program remains effective year after year.”

Value Considerations Beyond Price

While initial purchase price matters, the total cost of ownership for ESD uniforms extends beyond the invoice. Consider these factors when evaluating true value:

Garment lifespan significantly impacts overall costs. Higher-quality ESD uniforms may maintain their protective properties through more wash cycles, effectively lowering the per-wear cost despite higher upfront pricing.

Customization options like those offered with 2-piece ESD uniform sets provide dual functionality—combining branding with protection—potentially consolidating budget lines and enhancing professional appearance.

A supplier’s willingness to provide maintenance guidance, testing assistance, and replacement recommendations demonstrates their commitment to your program’s long-term success. The expertise shared in guides like those from NIST’s ESD research department emphasizes that proper maintenance extends effective lifecycle significantly.

Remember that ESD uniform failure can result in costly product damage and production delays far exceeding any savings from choosing cheaper, less reliable options.

Conclusion

After years in the industry, I’ve seen how ESD uniforms work as a vital shield against static threats in high-tech settings. These ingenious garments, with their conductive fabrics and Faraday Cage-like designs, channel static safely away, protecting sensitive electronics across healthcare, labs, and manufacturing. They’re more than just clothing—they’re a strategic defense that cuts costs and boosts safety.

I’m Dani from iBestUniform, where we’ve honed this technology for 14 years, offering over 200 designs to safeguard your operations. With my nine years of expertise, I can assure you that understanding how ESD uniforms work empowers smarter workplace decisions—equip your team with the right gear and watch reliability soar.

FAQ

-

Q1: What are ESD uniforms and how do they work?

A1: ESD uniforms are specially designed garments that incorporate conductive fibers to safely dissipate static electricity, thereby preventing damage to sensitive electronics.

-

Q2: How do ESD uniforms prevent static buildup?

A2: They prevent static buildup by using conductive materials and integrated grounding techniques that channel excess static charge away from the body.

-

Q3: What materials are used in ESD uniforms?

A3: ESD uniforms typically use blends of polyester with conductive elements such as carbon or silver fibers, which enhance their ability to dissipate static charges.

-

Q4: Do ESD uniforms lose effectiveness after multiple washes?

A4: Proper washing and maintenance can preserve their conductive properties; however, repeated laundering might gradually diminish their effectiveness if not done according to guidelines.

-

Q5: How is the Faraday Cage effect utilized in ESD uniforms?

A5: Many ESD uniforms mimic a Faraday Cage by encompassing the wearer in a network of conductive fibers, allowing static charges to be redirected safely to the ground.

-

Q6: Can ESD uniforms be used in all electronic manufacturing environments?

A6: Yes, they are widely adopted in various industrial and electronic manufacturing settings where static-sensitive components are at risk.

-

Q7: What is the role of conductive fabrics in ESD uniforms?

A7: Conductive fabrics play a crucial role by evenly dispersing static discharge across the garment, preventing localized charge buildup that could damage electronic components.

-

Q8: How do operational practices enhance the effectiveness of ESD uniforms?

A8: Regular maintenance, adherence to industry laundering standards, and proper storage ensure that ESD uniforms consistently perform by maintaining their static dissipative properties.

External Links

- NIST: Electrostatic Discharge (ESD) Research

- OSHA: Electrostatic Discharge (ESD) Safety Guidelines

- IEEE Xplore: Advances in ESD Protection Technology

- Statista: Electrostatic Discharge Statistics in Electronics

- OECD: Industrial Safety and Best Practices

- MIT Technology Review: Innovations in ESD and Static Control

- Reuters Technology: Manufacturing Safety Trends

- Harvard Business Review: Managing Operational Safety in Manufacturing

SEO Information

Title: Understanding ESD Uniforms: Protecting Electronics from Static

Description: Learn how ESD uniforms protect sensitive electronics in industries like healthcare and manufacturing. Discover the technology behind conductive fabrics and effective design strategies that enhance workplace safety and reliability.

URL: understanding-esd-uniforms-protecting-electronics-from-static

Primary Keyword: How ESD Uniforms Work

Blog Categories

Basic Knowledge